The topic for this fall’s Regional Economic Indicators Forum (REIF), scheduled for October 26, 2021, is the Circular Economy. What is this concept and can local businesses use the concept to their advantage? In preparation for the REIF event, we at the BBER have been doing some of our own research on the topic.

According to the Sustainable Growth Coalition, a Minnesota-based, business-led partnership seeking to advance corporate sustainability, the circular economy is an economic system aimed at eliminating waste and the continual use of resources.

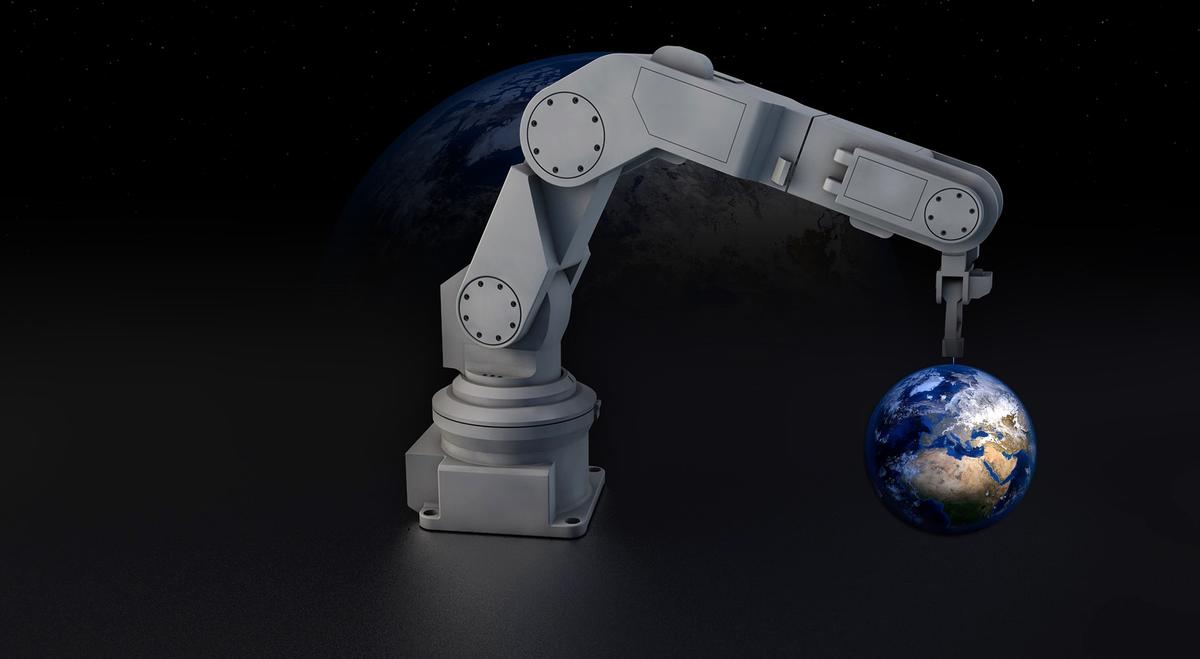

In contrast to the traditional linear economy—sometimes referred to as the “take, make, and dispose” model that primarily seeks to take raw materials from the earth, make them into products, and then dispose of the waste—the circular economy aims to develop recyclable and sustainable resources.

But the circular economy is not just about more recycling. The concept starts with using resources that have already been extracted. Companies are also encouraged to incorporate eco-design, which is designing products so they last longer and can easily be dismantled for their parts. And in many cases, under the circular model, consumers lease products rather than purchase them so that when the product reaches the end of its life, it goes back to the manufacturer to be disassembled and repurposed. In a circular economy, nothing goes to landfill.

Minnesota is a leader in material reuse and circular innovation. Nearly 30 Minnesota-based businesses and organizations—including BARR Engineering, Best Buy, Blue Cross Blue Shield, Ecolab, Great River Energy, and many more—are members of the Sustainable Growth Coalition, which is working to advance the circular economy. According to the organization’s website, businesses benefit from incorporating the circular economy through a reduction in operating costs, new business models, improved workforce outcomes, and increased consumer demand.

One member of the Sustainable Growth Coalition is 3M, a Minnesota-based company with manufacturing sites worldwide. 3M is a leader in building circularity into its operations. Recent advancements include increasing recycled content and bio-based plastics and designs to decrease overall plastic use. One example of this is 3M’s Scotch-Brite Greener Clean Non-Scratch Scrubbers, made with 75% post-consumer recycled plastic and encased in recyclable packaging made from 100% recycled content.

Tennant, another example of a company that embraces the circular economy and one of the companies to be featured at the REIF this fall, is a floor cleaning equipment and service provider based in the Twin Cities. In 2014, Tennant implemented its RECON program, which involves reconditioning its previously owned cleaning equipment and reselling the products at a discounted price. By offering a refurbished product, Tennant is reducing their overall resource footprint. This innovative program has saved the company money and increased its customer base.

In a resource-constrained world, advancing a circular economy means moving away from the costly extraction of limited raw materials. Under the circular economy, consumers, retailers, recyclers, and manufacturers are working together to create a closed-loop, developing a genuinely circular and sustainable model of growth.